Material Selection for Butt Weld Fittings Choosing the right material is the first step in selecting...

What Makes Butt Weld Equal Tees Essential for Piping Systems?

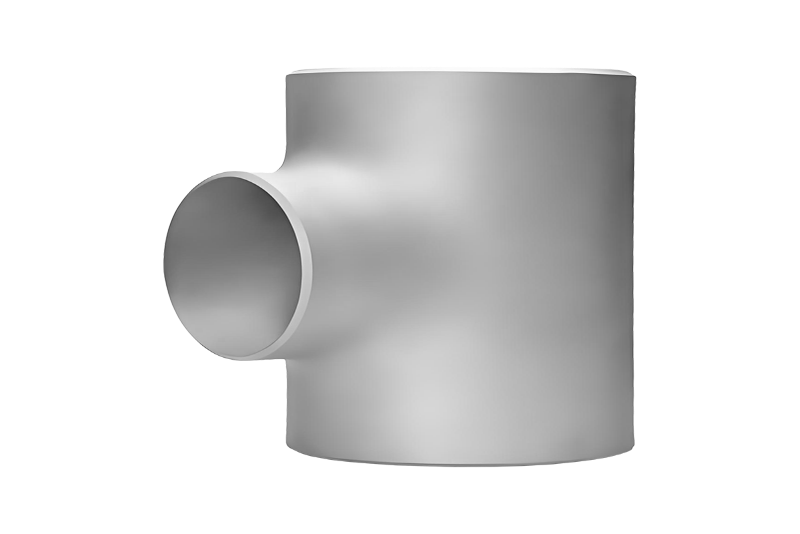

A butt weld equal tee is a type of pipe fitting used to connect three pipe sections of the same diameter at a T-junction. Its design allows for smooth flow transitions and structural integrity in piping systems. Widely used in industries such as oil and gas, chemical processing, power generation, and water distribution, the butt weld equal tee is preferred for high-pressure and high-temperature applications. Its welded connections provide leak-proof joints and maintain the mechanical strength of the piping system.

What are the key features of butt weld equal tees?

Understanding the core features helps engineers and designers select the right fitting for their system requirements.

Material composition

Butt weld equal tees are typically manufactured from high-quality metals such as carbon steel, stainless steel, alloy steel, or nickel alloys. The material choice depends on factors like operating temperature, pressure, and chemical compatibility. Stainless steel, for example, provides excellent corrosion resistance for chemical and food processing applications.

Design and dimensions

Equal tees have three openings of identical diameter. This uniformity allows for balanced flow distribution and simplified installation. The fittings are manufactured according to standards such as ASME B16.9, ensuring consistency in dimensions, wall thickness, and pressure rating. Proper sizing is critical for avoiding turbulence and pressure drops in the system.

End connection

The butt weld connection involves aligning the pipe ends and welding them directly to the tee. This method provides a strong, permanent joint capable of withstanding high stress, pressure, and thermal expansion. The smooth internal surface reduces flow resistance and prevents accumulation of debris, making it ideal for sanitary and industrial pipelines.

How is a butt weld equal tee manufactured?

The manufacturing process ensures durability, precision, and compliance with industry standards.

Forming and shaping

Typically, the tee is formed using hot-pressing, hot-rolling, or seamless forging methods. The base material, usually a steel pipe, is heated and pressed into the T-shape. This process enhances the structural integrity and uniformity of the fitting.

Welding and finishing

After forming, the tee may undergo additional welding to ensure dimensional accuracy. Heat treatment processes such as normalizing or annealing relieve stress in the material, enhancing strength. The surfaces are then finished by polishing or coating to prevent corrosion and ensure smooth flow.

Quality inspection

Butt weld equal tees undergo rigorous quality checks, including dimensional verification, radiographic inspection, and hydrostatic testing. These inspections ensure the fittings meet standards for pressure, material integrity, and leak-proof performance.

What are the common specifications and standards?

Choosing fittings that comply with recognized standards ensures safety and compatibility with other system components.

| Standard | Specification | Details |

| ASME B16.9 | Dimensions & tolerances | Covers wall thickness, diameter, and end preparation for butt welding |

| ASTM A234 | Material grade | Covers carbon steel, alloy steel, and stainless steel fittings for pressure service |

| ISO 9001 | Quality management | Ensures consistent manufacturing quality and process control |

What are the advantages of using butt weld equal tees?

Butt weld equal tees offer multiple benefits over other types of pipe fittings.

- High strength and durability — Welded joints maintain mechanical integrity even under high pressure.

- Leak-proof connections — Butt welds create continuous joints that minimize leakage risk.

- Smooth internal flow — Reduces turbulence, pressure drops, and accumulation of debris.

- Compatibility — Meets standard dimensions and material grades for integration into industrial piping systems.

- Versatility — Suitable for high-temperature, high-pressure, and corrosive environments.

How to select the right butt weld equal tee?

Correct selection is crucial to ensure safety, efficiency, and longevity of the piping system. Key factors include:

- Pipe diameter and wall thickness — Ensure the tee matches the pipeline to maintain pressure rating and flow capacity.

- Material compatibility — Choose steel grade based on temperature, pressure, and chemical exposure.

- End preparation — Ensure proper beveling for welding to achieve a strong, defect-free joint.

- Standard compliance — Select tees manufactured under recognized industry standards for reliable performance.

What are installation and maintenance best practices?

Proper installation and maintenance ensure long-term performance and safety.

Installation tips

Before welding, clean pipe ends and tee surfaces to remove rust, oil, and debris. Use alignment tools to position the tee precisely. Ensure the correct welding technique and filler material are used according to the pipe and tee specifications. Avoid excessive heat to prevent distortion.

Maintenance guidelines

Regular inspections for corrosion, weld integrity, and leakage are essential. For high-pressure or corrosive systems, consider protective coatings or cathodic protection. Promptly address any damage or signs of wear to prevent system failure.

Common mistakes to avoid with butt weld equal tees

Awareness of common errors can prevent costly downtime and safety hazards.

- Mismatched material grades — Leads to corrosion, leakage, and reduced lifespan.

- Improper alignment before welding — Can cause stress concentration and flow inefficiencies.

- Ignoring standard compliance — May result in incompatibility with other system components.

- Skipping regular inspections — Reduces early detection of defects and maintenance planning.

Conclusion

Butt weld equal tees are essential components in industrial piping systems, offering durability, leak-proof performance, and smooth flow transitions. By understanding the types, materials, standards, and best practices for installation and maintenance, engineers and operators can ensure efficient, safe, and long-lasting piping networks. Proper selection, installation, and care of butt weld equal tees not only enhance system performance but also reduce maintenance costs and operational risks.

Stay Informed About Our Recent Events

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى